LUKAS IR-sintering oven and induction systems

Our broad portfolio of sintering ovens enables us to create a customized oven for every application. Each model delivers perfect sintering results with a high level of user-friendliness. The sintering process of LUKAS oven systems is controlled by modern software.

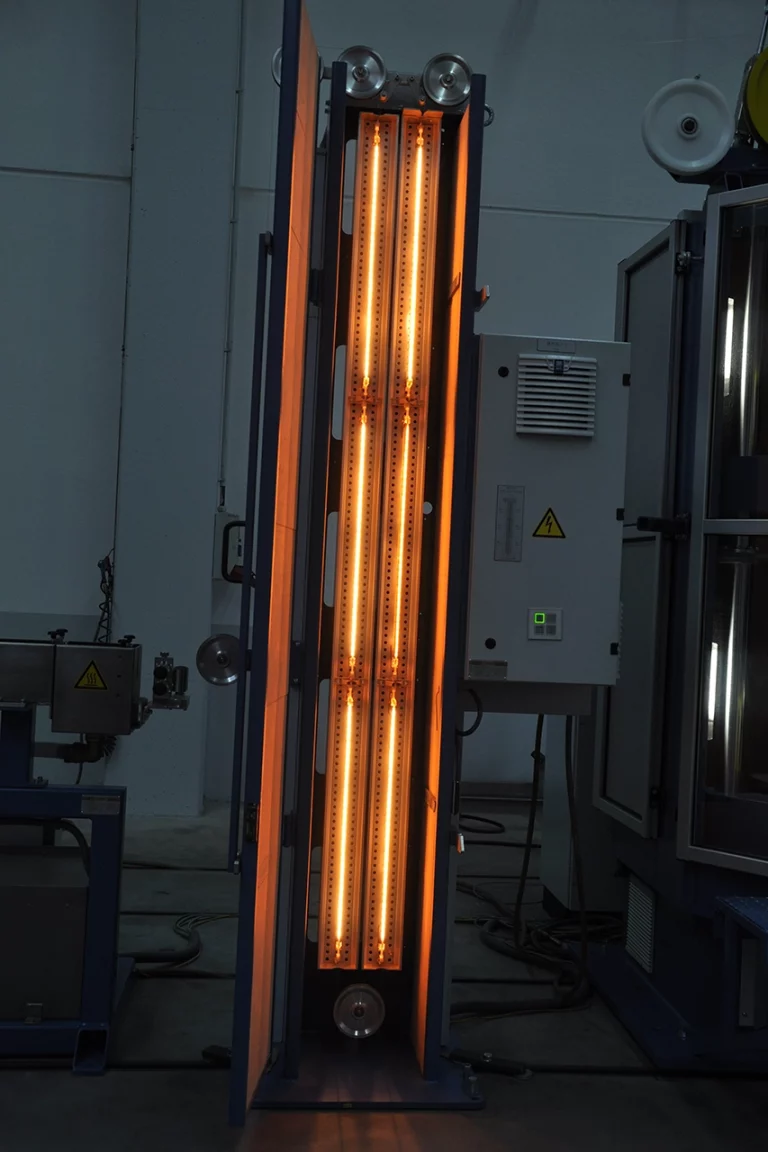

Vertical infrared sintering oven

Our vertical infrared sintering ovens are suitable for sintering PTFE and PI insulated conductors and much more.

Highlights:

- Energy-efficient heating with gold-coated IR slot radiators

- Fast-reacting emitters enable precise control of the sintering process

- Sliding oven shaft

- Extraction option for exhaust gases at the top of the oven

- Compact design

Horizontal infrared sintering oven

Our horizontal infrared sintering ovens are suitable for sintering PTFE and PI insulated conductors, melting Daglas or drying varnish.

Highlights:

- Single- or multi-pass operation

- Precise temperature control

- Sliding oven shaft

- Extraction option for exhaust gases at the top of the oven

- Robust construction

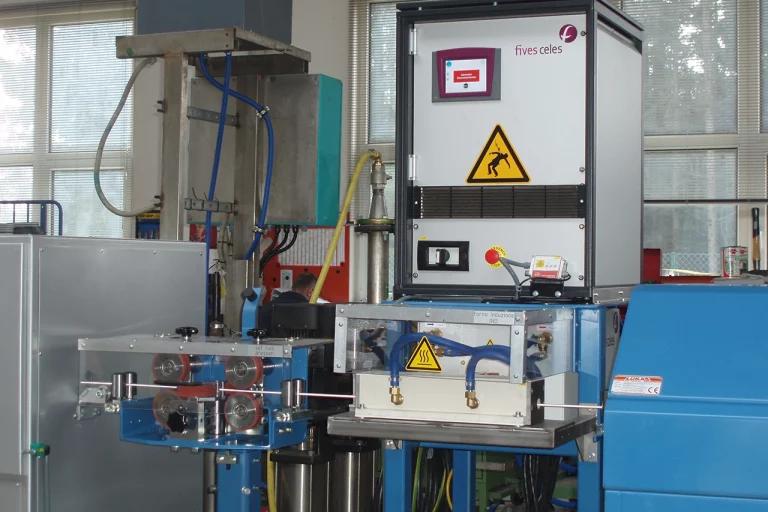

Induction systems

LUKAS induction systems stand for high efficiency and economy. For non-contact heating of electrically conductive materials, we place the workpieces in the alternating magnetic field of a coil so that eddy currents are induced in them, which lead to heating. The simple integration and easy automation of individual production processes are decisive advantages of our systems.

Our medium and high-frequency generators with different outputs can be universally adapted to different heating tasks.

A new type of inductor delivers unprecedented efficiency, especially with flat conductors.