LUKAS individual components

Our individual components for your wire and cable production guarantee smooth production processes. Optimally matched to each other, our systems deliver top performance both on their own and in combination.

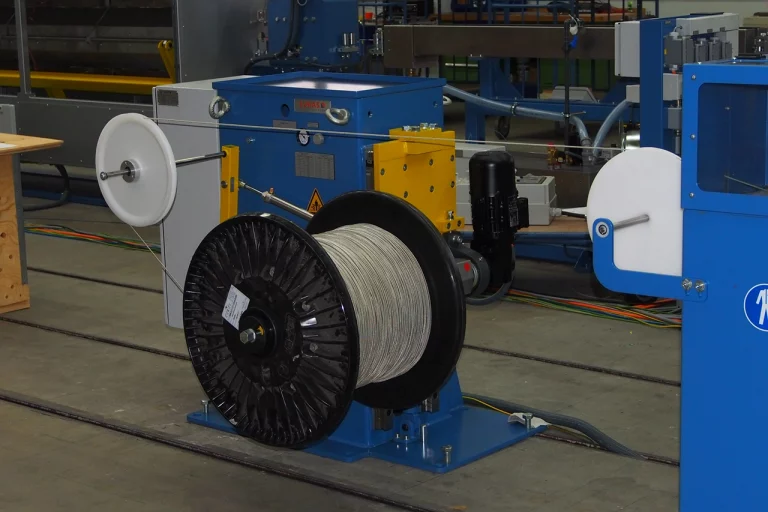

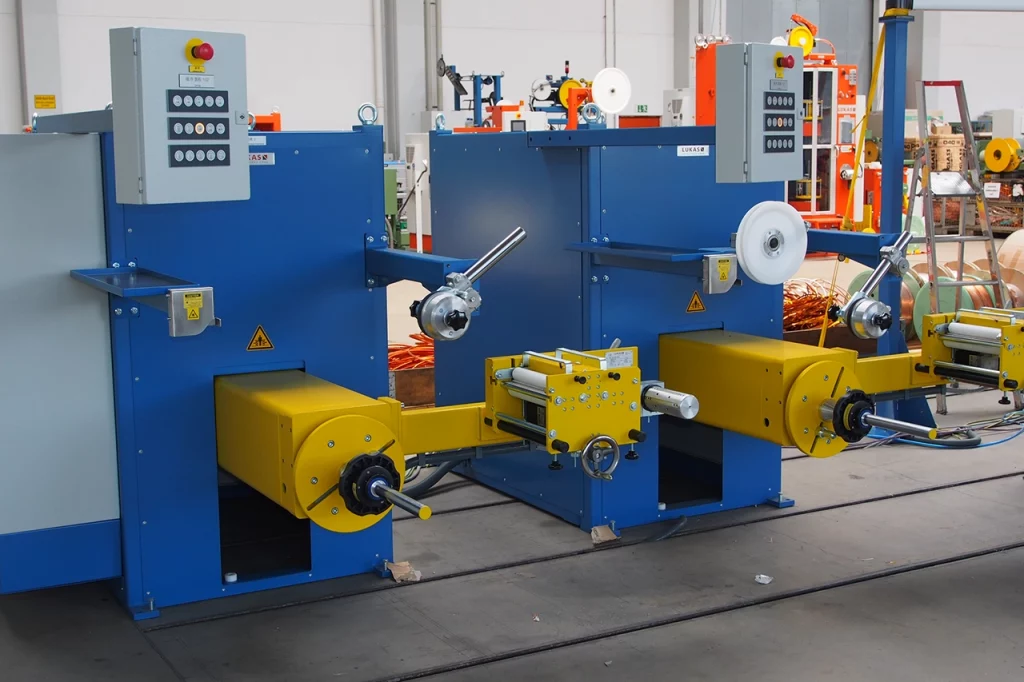

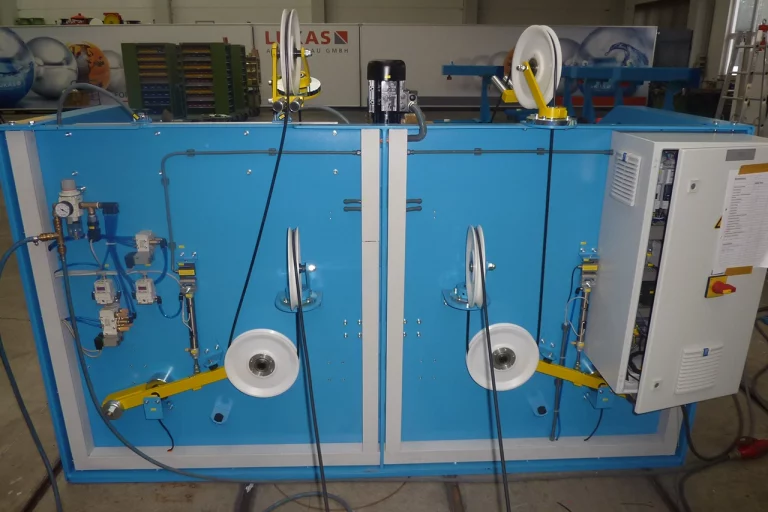

LUKAS wire pay-offs

LUKAS wire pay-offs are available in various designs:

Driven tangential pay-offs with flying shaft

Particularly suitable for:

- Round wires, wire bundles, stranded wires and insulated cables

- Application in stranding machines, extruder systems, annealing systems, rewinding stations and taping machines

- Single, double or multiple pay-offs

- Applications with traversing reel

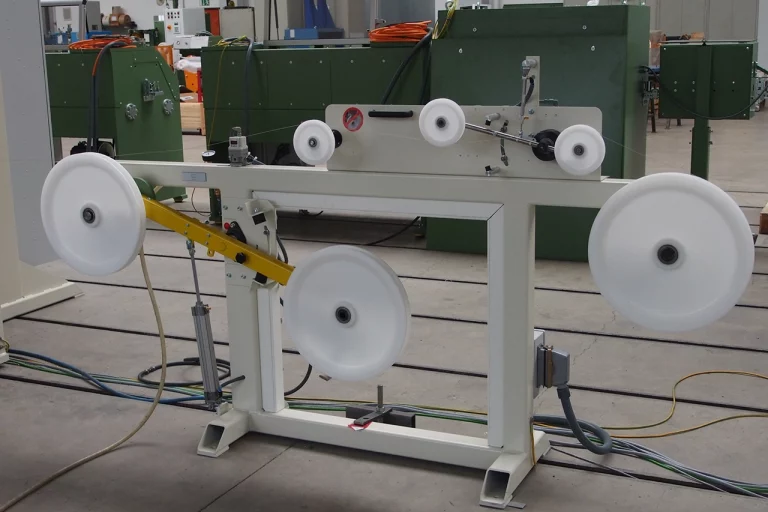

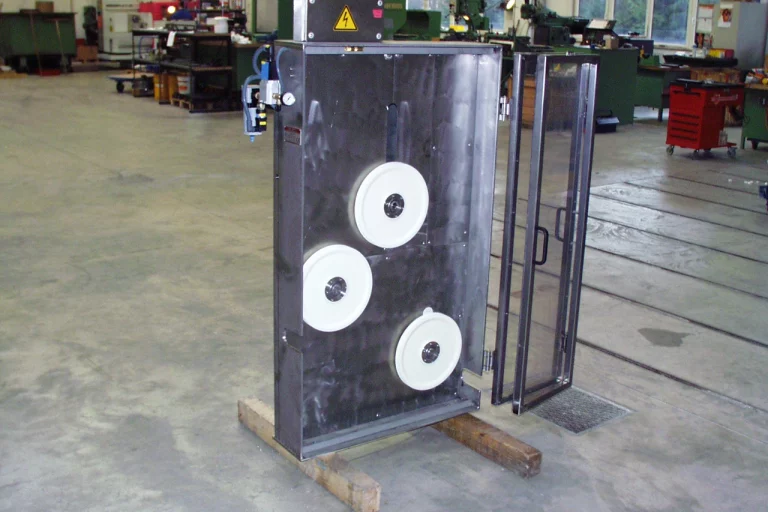

Pay-off pintle type

Particularly suitable for:

- Round wires, wire bundles, stranded wires and insulated cables

- Application in stranding machines, extruder systems, rewinding stations and electroplating systems

- Available in horizontal and vertical version.

- Optional with traversing reel

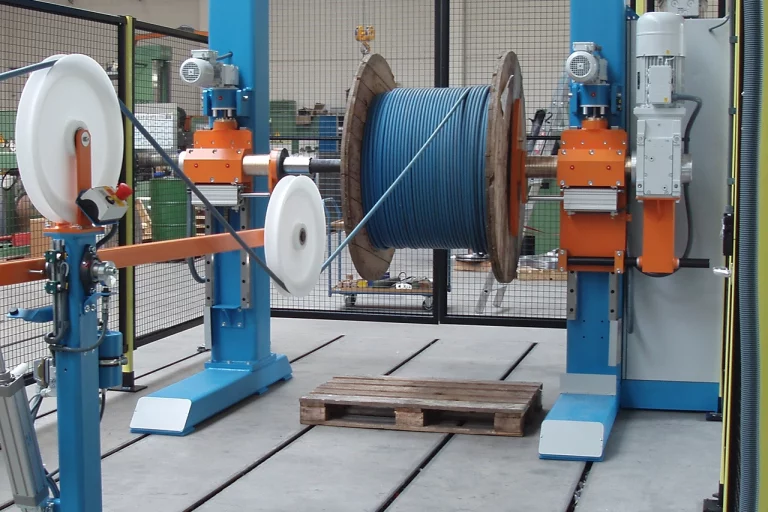

Pay-off portal type

Particularly suitable for:

- Cores and cables

- Application with fixed frame or telescopic crossbar

- Available with traversing reel

Pay-off flyer type

Particularly suitable for:

- Round wires, wire bundles and strands

Available as powered or braked with hysteresis brake version.

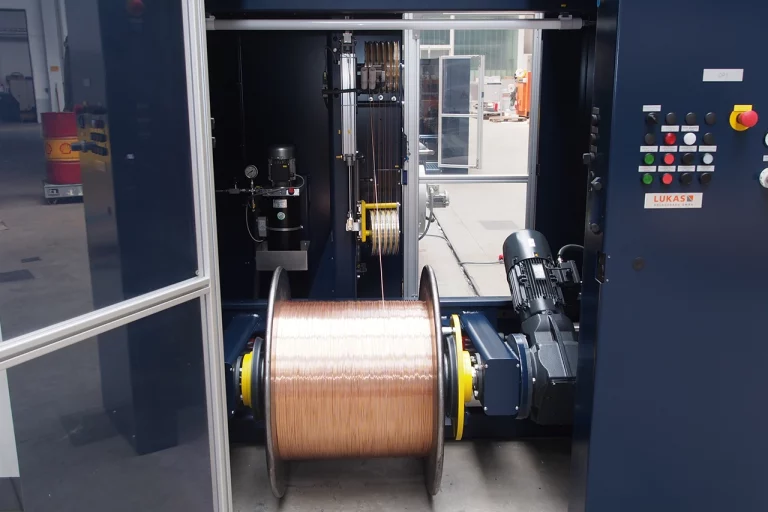

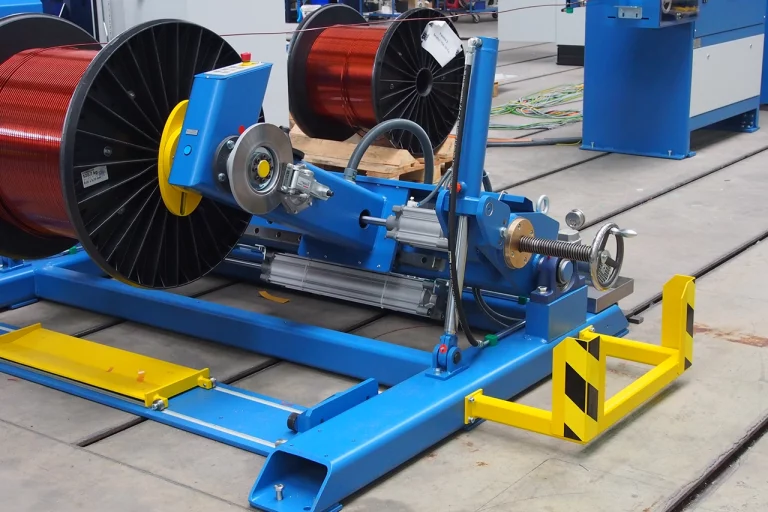

LUKAS take-up

LUKAS take-ups are available in various designs:

Pintle type take-up

Particularly suitable for:

- Round wires, wire bundles, stranded wires and insulated cables

- Application in stranding machines, extruder systems and rewinding stations

- Available in horizontal version

- Optional with traversing reel

Take-up for container/ universal take-up

(also as multiple take-up)

Particularly suitable for:

- Container and optionally also for reels

Portal type take-up self traversing

(also with fixed frame or telescopic crossbar)

Particularly suitable for:

- Cores and cables

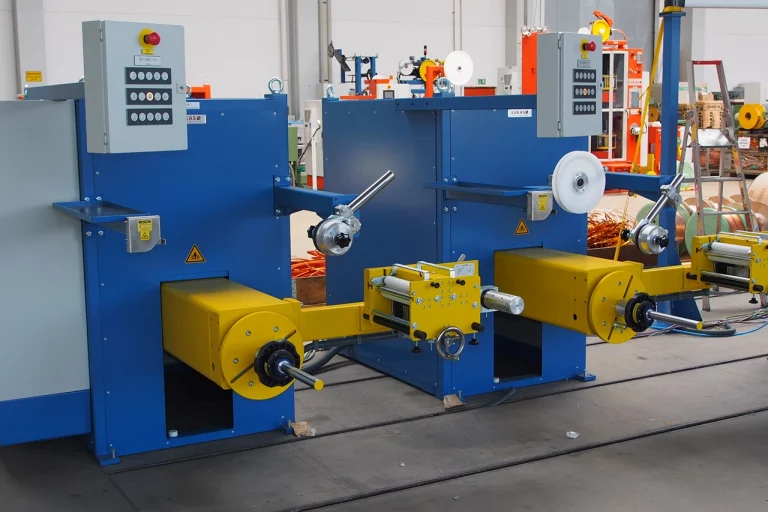

Take-upwith cantilevered shaft

Particularly suitable for:

- Winding of round wire, wire bundles, stranded wires and insulated cables

- Application in rewinding systems, varnish application, stranding machines, extruders, drawing machines, spinning and taping systems

Available with horizontal or vertical spool shaft, also traversing.

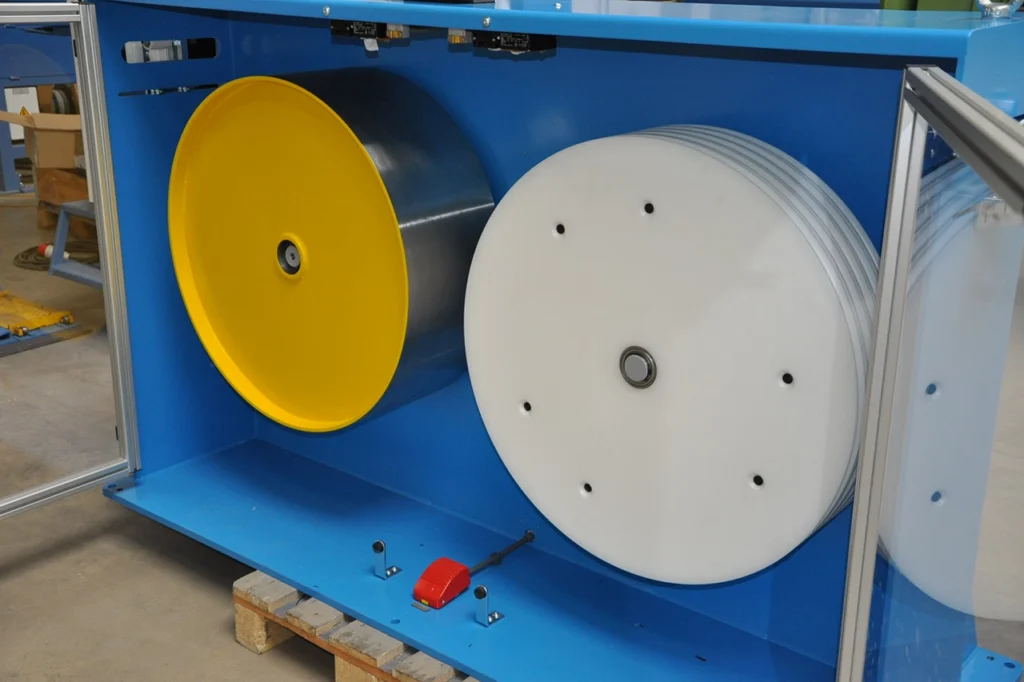

LUKAS wire accumulator

Our wire accumulator is suitable for wires and cables and consists of a stable, vertical linear guide unit, a fixed and variable roller package, the electrical equipment and, as an option, a force sensor and a protective fence. Both vertical and horizontal designs are possible.

All components are mounted on a sturdy base frame.

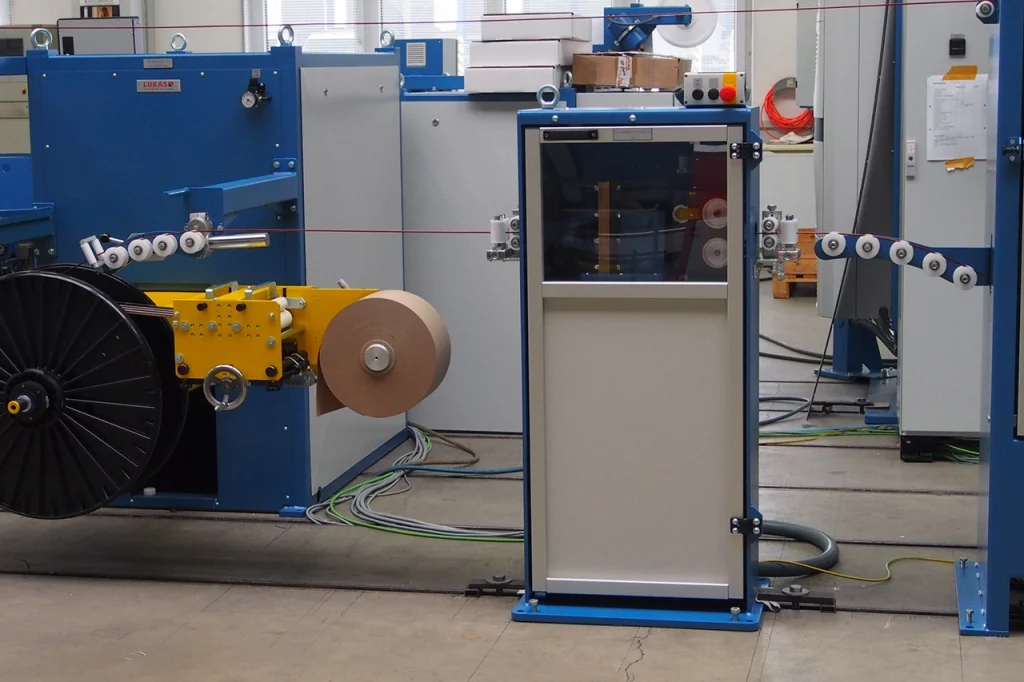

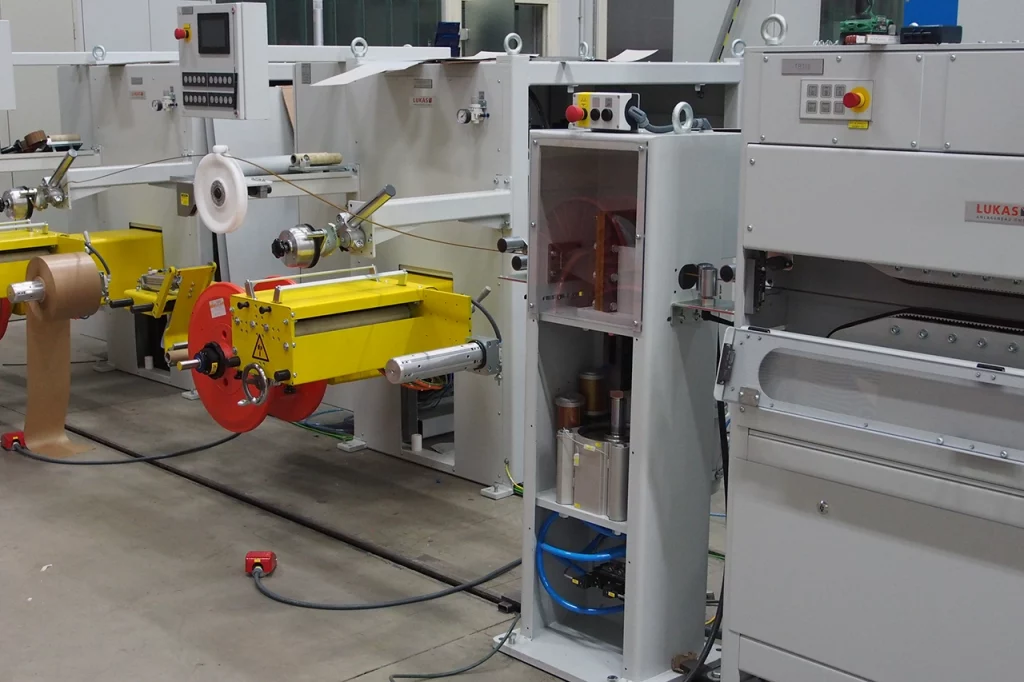

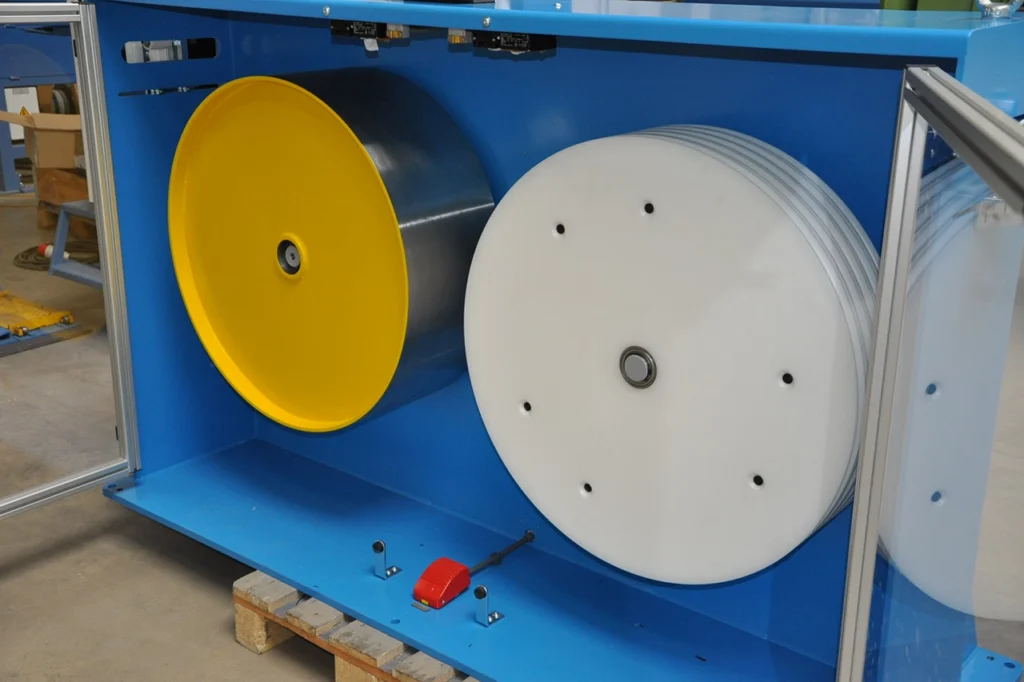

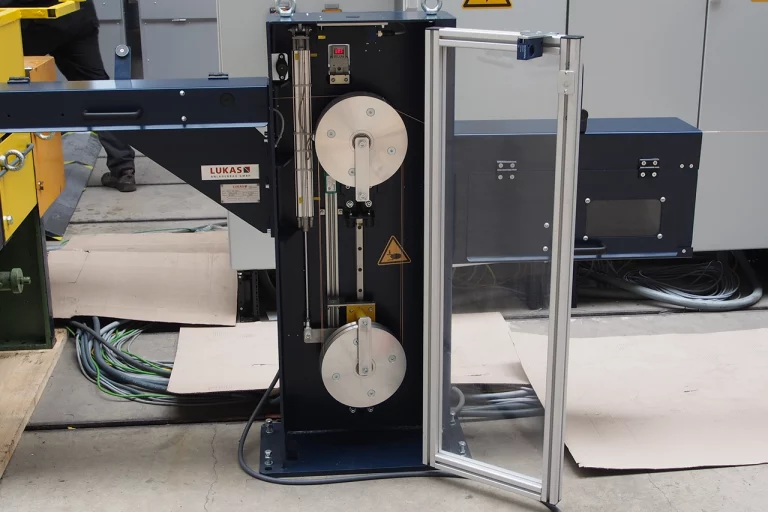

LUKAS paper feeder

To prevent surface damage, our paper feeder automatically inserts a layer of paper between each (umpteenth) layer of wire. Both the time of insertion and the length of the paper can be set. In addition to integration into our winders, attachment to winders from other manufacturers is also possible.

LUKAS brush cleaning device

Our brush cleaning device is used for the mechanical cleaning of bare conductors, for example before the taping process. It can be equipped with two or four brushes. It is optionally available with water cleaning and compressed air blow-off to remove dust residues. Highlights include speed-controlled drives and rotating brushes that can be adjusted to suit the wire width and thickness.

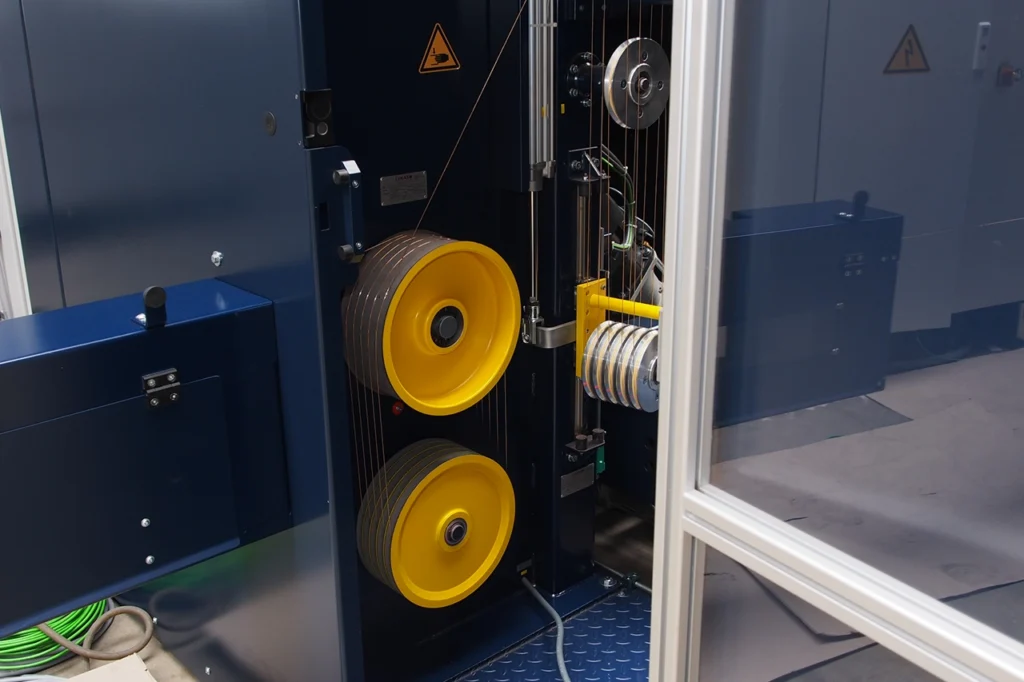

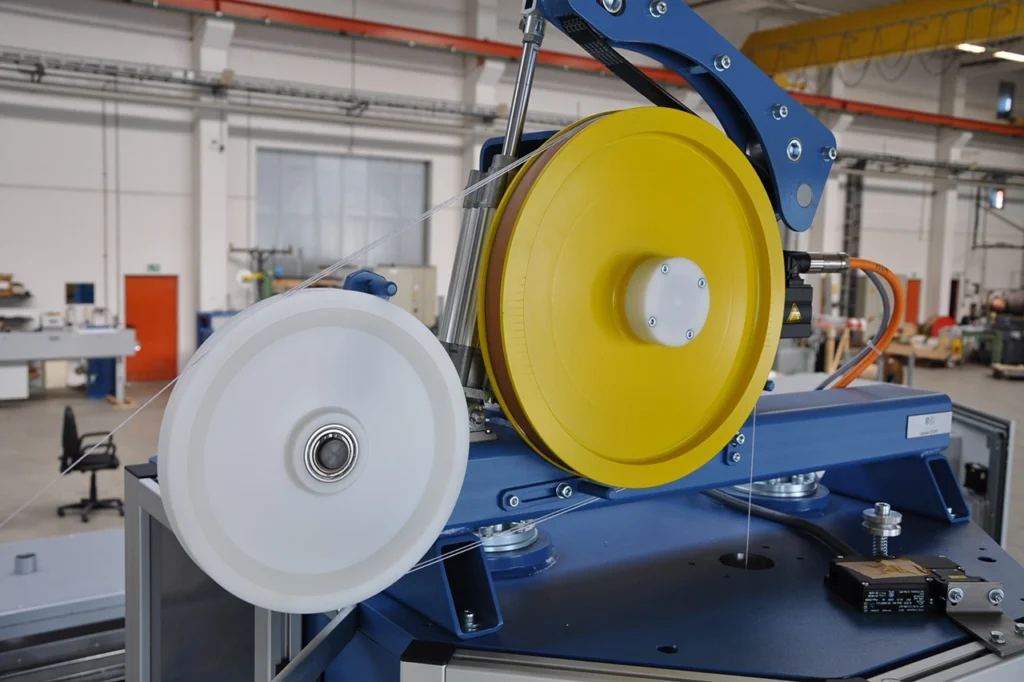

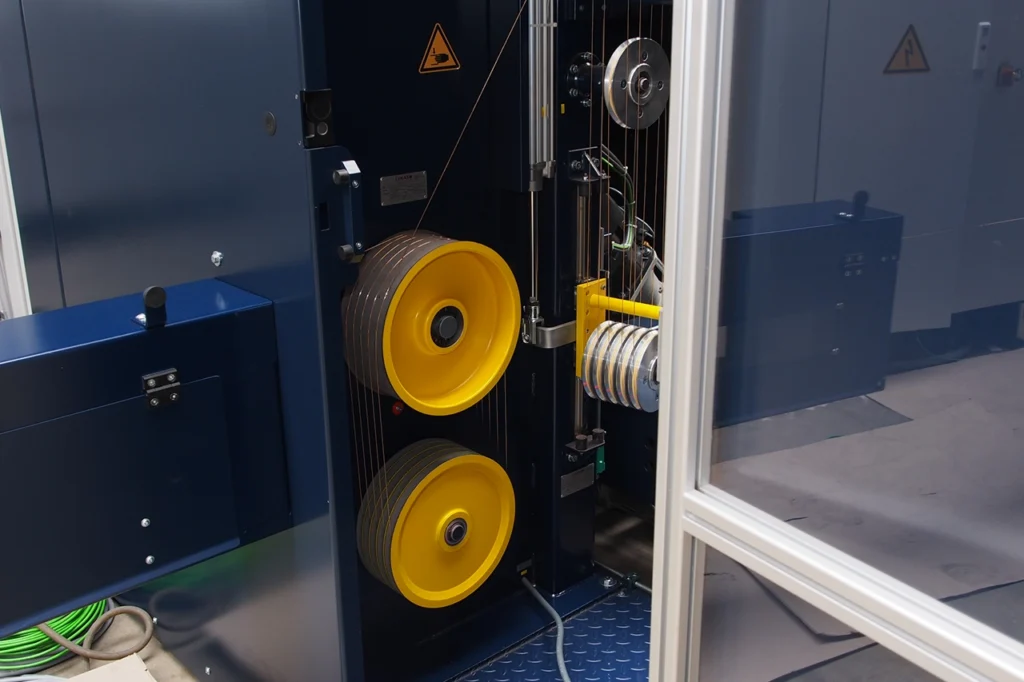

LUKAS caterpillar/Capstan

Our haul-off solutions are used worldwide for a wide range of industry applications: our caterpillar haul-off has two drives for flat wire lines; our cable caterpillar with one drive is perfect for optimum guidance of large-format cables. Our single-disc capstan is suitable for tension control to maintain a constant product tension. Our range is completed by the double capstan.

LUKAS haul-off applications

- Spinning and taping systems

- Electroplating systems

- Rolling mills

- Rewinding stations

- Stranding machines

- Extruder lines

- Annealing and sintering lines

- Varnishing lines

LUKAS haul-off versions

- Optional speed, tension or dancer control

- Synchronization mode also possible with caterpillars

- Different surface materials and contours depending on the product

- Integrated water cooling for applications with thermal processes

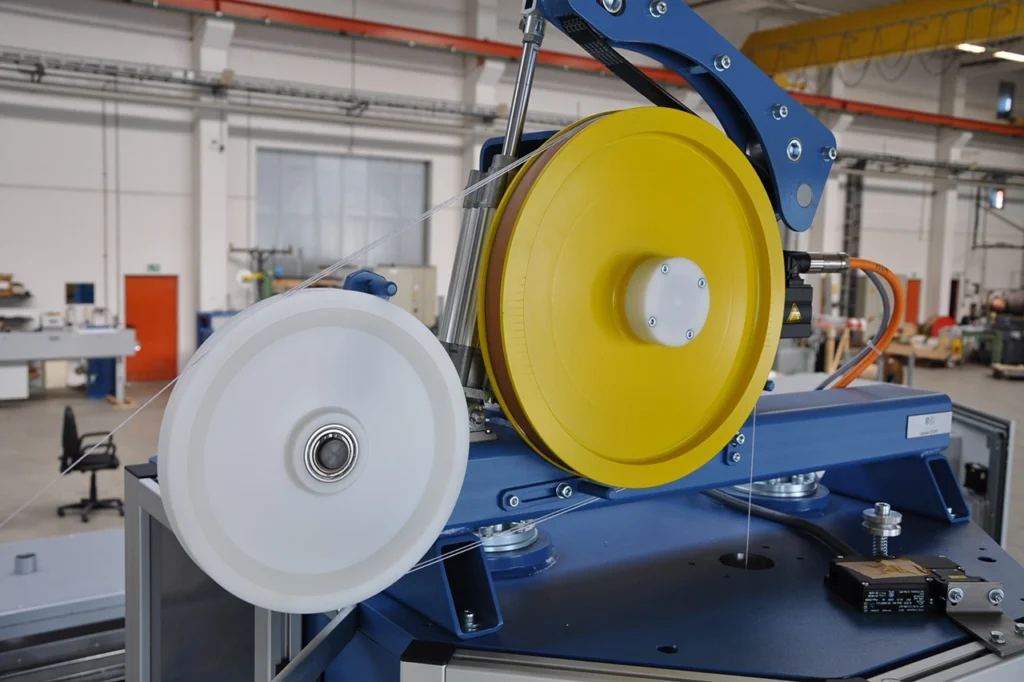

LUKAS Dancer

Our dancer solutions are used worldwide for a wide range of industry applications: Our swing dancer is available in two versions: with a single wrap on a swivel bearing or fixed; also with multiple wraps. The tension can be set using a weight or air pressure. A precision pressure regulator can also be used to set the tension from the PLC. Our linear dancer is perfect in case of space problems.

LUKAS dancer applications

- Spinning and taping systems

- Electroplating systems

- Rolling mills

- Rewinding stations

- Stranding machines

- Extruder lines

- Annealing and sintering lines

- Varnishing lines

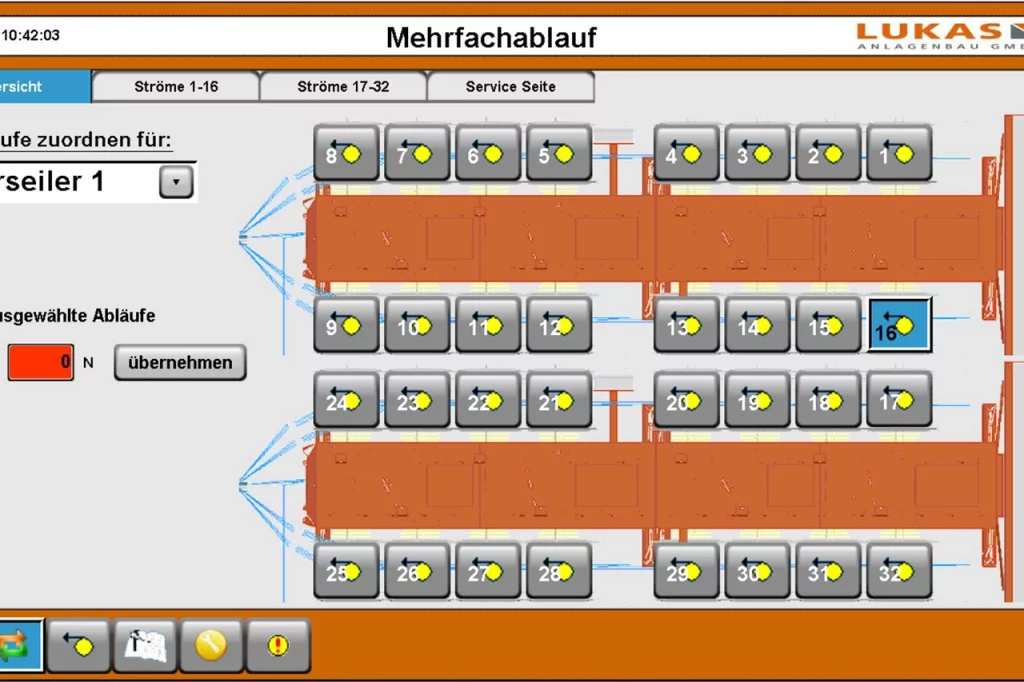

LUKAS line control

All lines are equipped with a line control with touch screen, usually with a 10″ screen size (optionally up to 21″). Smaller units are also used for individual components or as secondary visualization. As an option, our line control systems offer the possibility of remote maintenance, i.e. access to the control program via the Internet, as well as the possibility of OPC connection to higher-level SCADA systems.

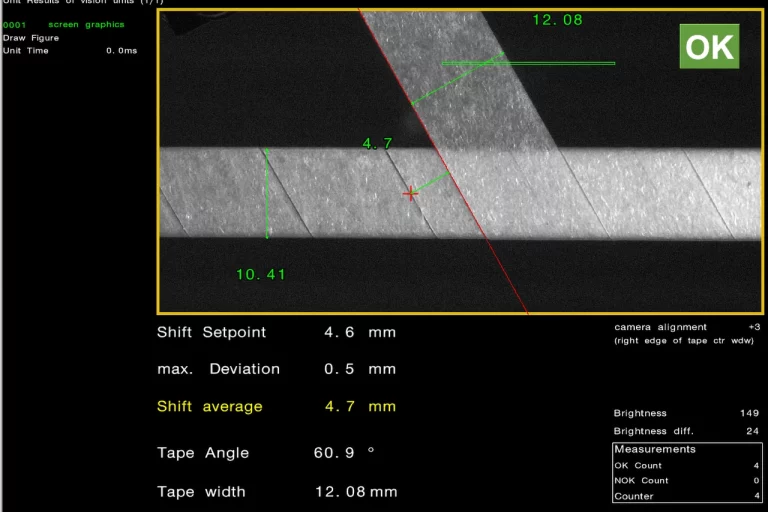

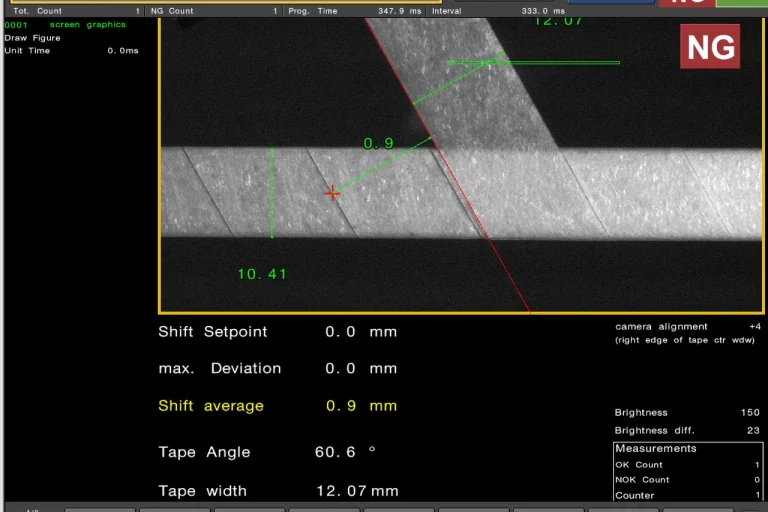

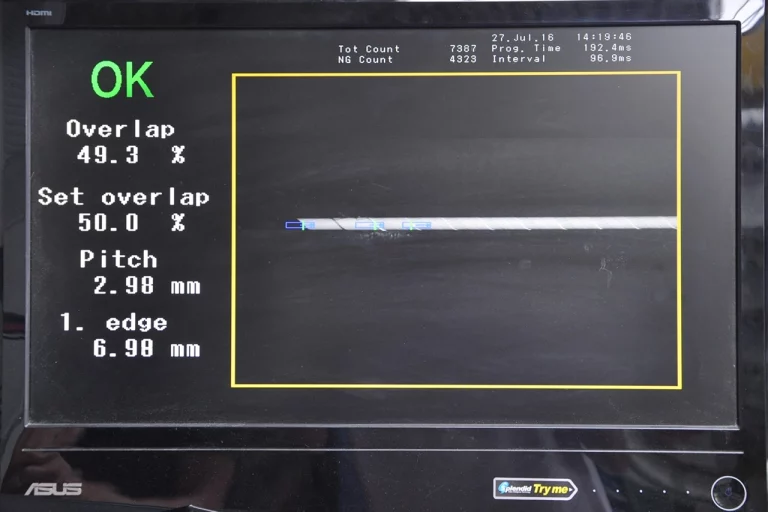

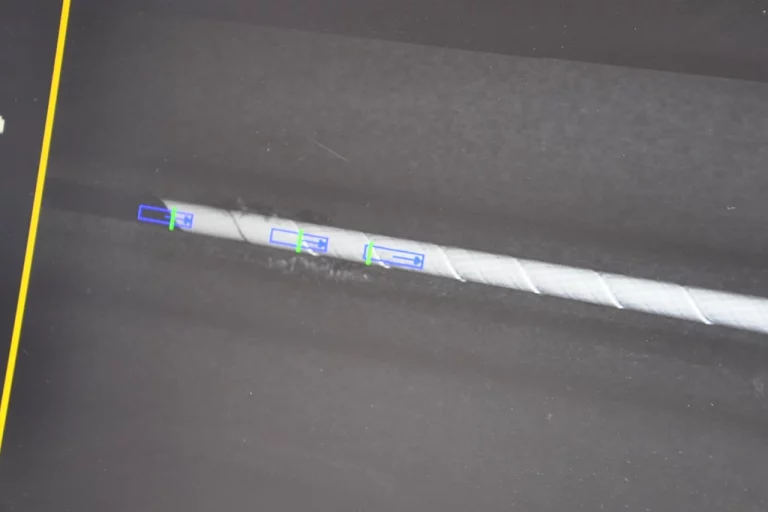

LUKAS image processing

One or more camera systems are used to monitor the surface of the conductor during taping. Depending on the application, this can also be done directly at the contact point of the tape.

Appropriate software can be used to record and automatically adjust the pitch, overlap or offset of two layers, for example.

We integrate these additional components into a line:

- Straightening rollers

- Diameter measuring devices

- Spark tester

- Precision meter counter

- Speed sensors for control

- Sets of delection pulleys (also with air cooling)

- Set of pressing rollers (in conjunction with induction heaters)

- and much more