LUKAS taping lines for the best products

Our LUKAS taping lines are optimized for the production of high-quality electrical conductors. Manufacturers all over the world rely on our machines and taping lines because they guarantee the best products for industry-specific requirements. Space-saving and profitable in production.

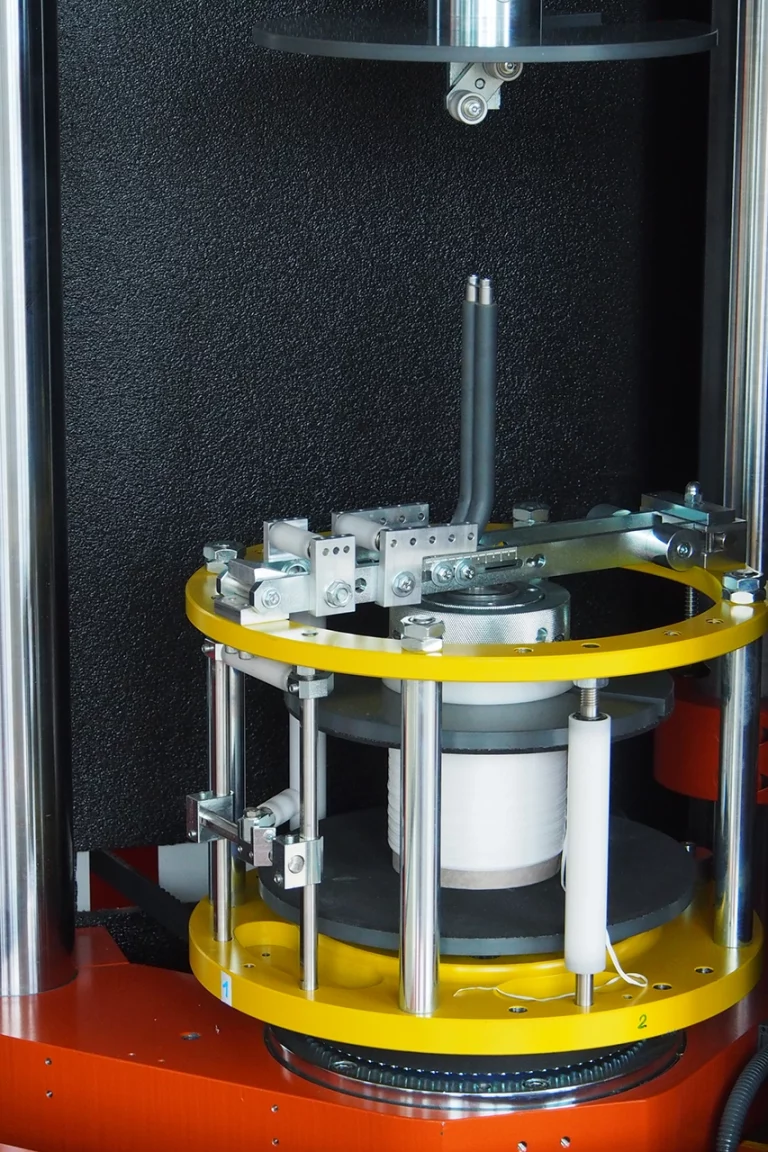

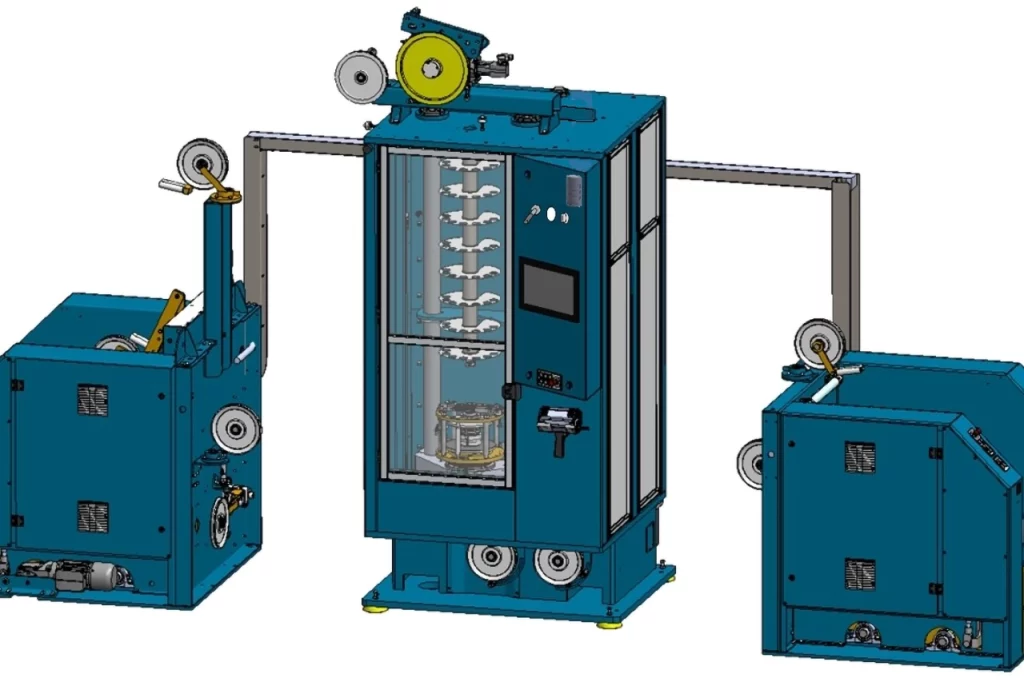

Vertical taping line

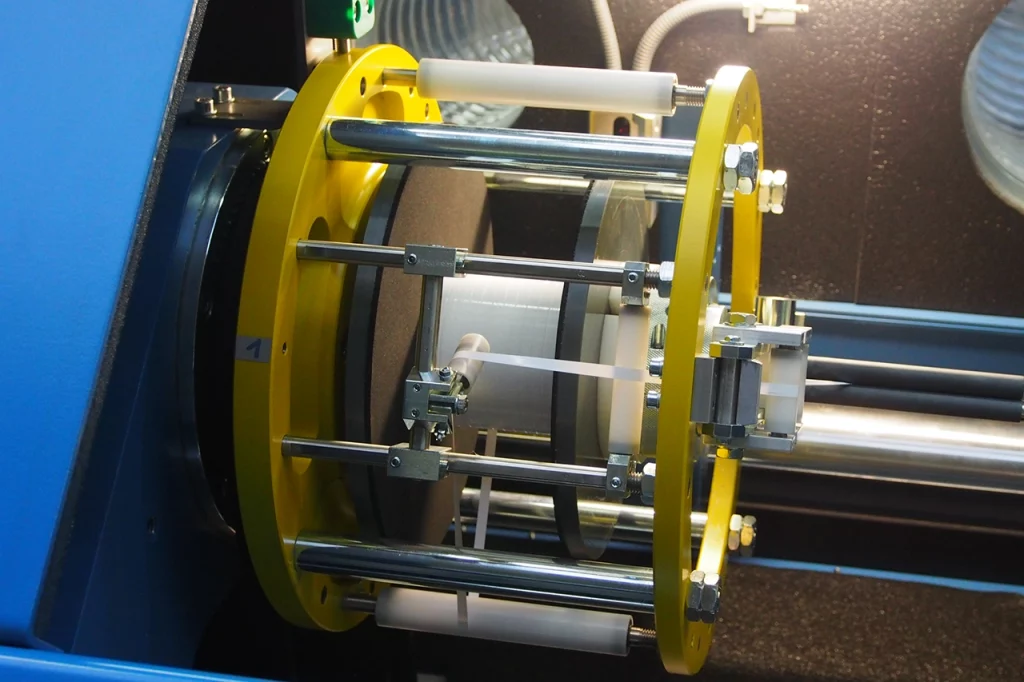

Our vertical taping units are particularly suitable for the production of wires and cables that are also suitable for smaller bending radii. The machines enable maximum performance with a small footprint. The vertical taping units can alternatively be designed with one or more taping heads. They are suitable for processing polyester, PTFE, Kapton, mica, metal tapes, fleece, laminated aluminum tapes and much more. Variants for Daglas and glass fiber are also available.

The taping heads can be designed in two versions: Taping head with driven Kops or taping head with driven Kops and torque feedback with sensor.

LUKAS vertical taping units can be ideally adapted to the requirements of the applications in terms of tension and prevention of faults thanks to the variants tape tension control via adjustable torque curve, torque feedback with sensor and hollow shaft drive.

The taping heads are synchronized with an electronic gearbox to the capstan – this ensures high accuracy of the taping pitch. The wedge clamping system ensures secure clamping and centering of the tape reels even at high speeds. The laser sensor continuously records the tape reel diameter.

As an option, LUKAS vertical taping machines can be equipped with a stroboscope with speed synchronization for precise observation of the taping process – including an adjustable viewing angle.

The technical properties can be optimally adapted to the specific production requirements.

The vertical taping machines are very versatile:

- They are suitable for applying tapes and yarns of all kinds (mica, polyamides, polyimides, PTFE, paper, polyester, laminated tapes, aluminum foil, metal, fiberglass, etc), both on single wires or strands as well as single or multi-core cables

- The taping heads can work with both cross wraps and pads

- Each taping module can be equipped with one or two taping heads, which saves additional space in production

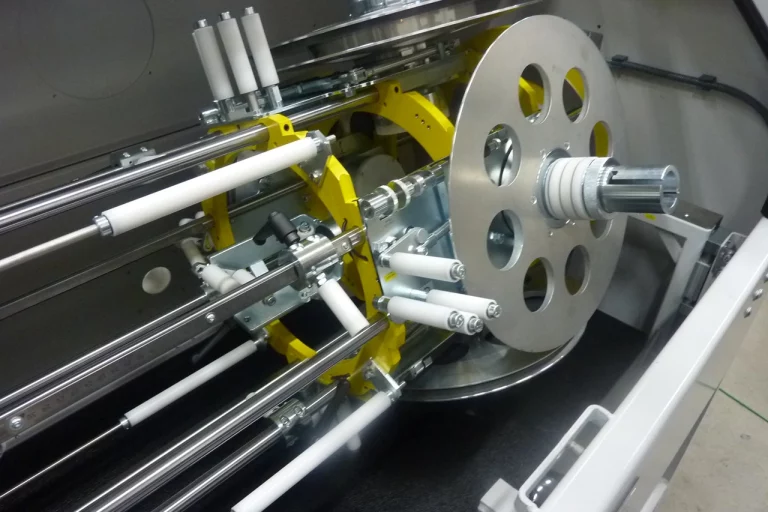

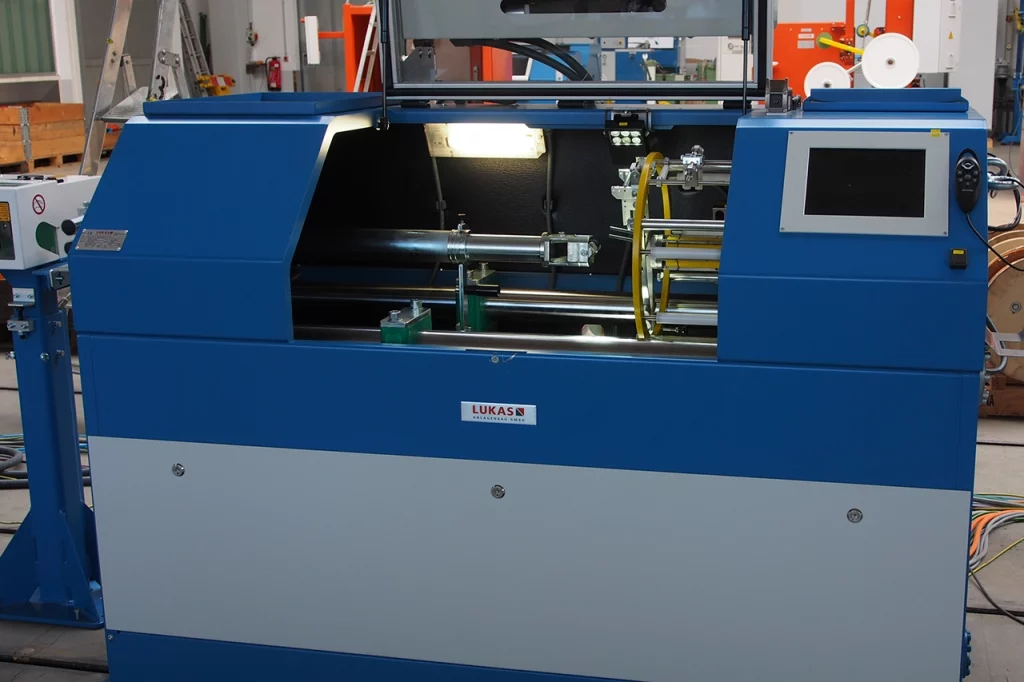

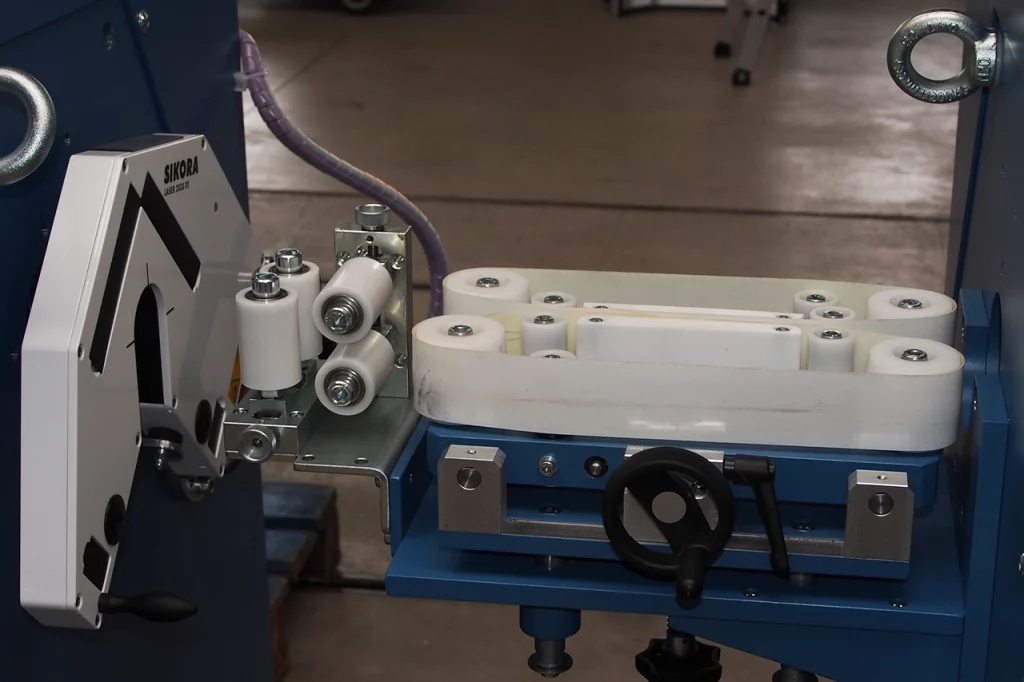

Horizontal taping machine

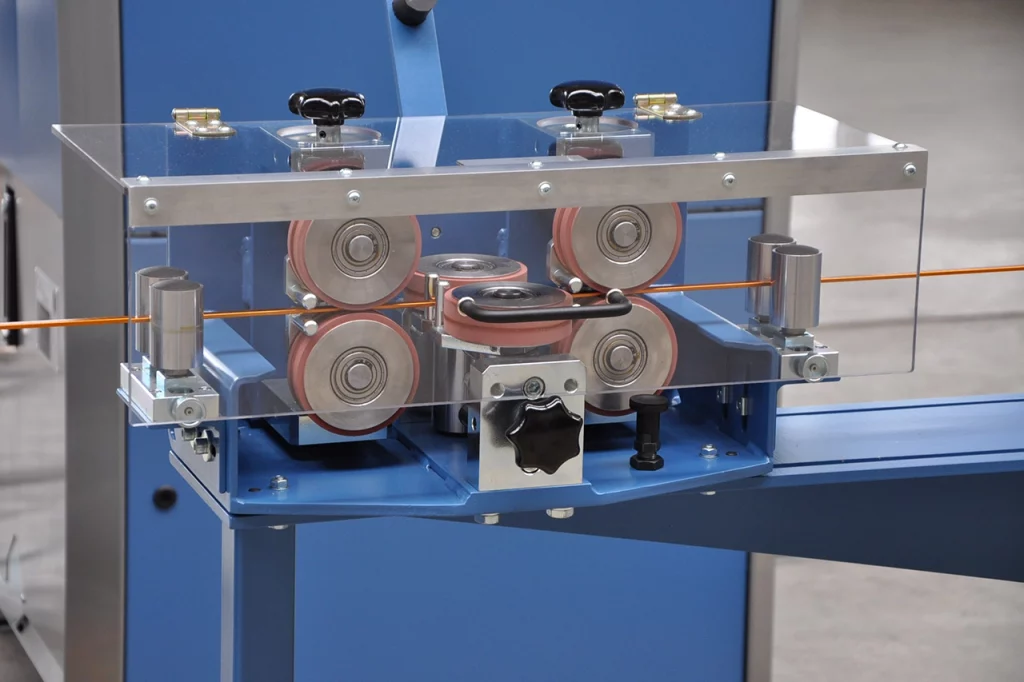

Our horizontal taping machines are perfectly suited for processing a wide range of different taping materials thanks to the use of different taping tools: They are suitable for processing polyester, PTFE, Kapton, mica, metal tapes, fleece, laminated aluminum tapes and much more. Variants for Daglas and glass fiber are also available. Up to five taping units can be synchronized in one line. The taping heads can be designed in two versions: Taping head with driven Kops and taping head with driven Kops and torque feedback with sensor.

LUKAS horizontal taping units can be ideally adapted to the requirements of the applications in terms of tension and prevention of faults thanks to the tape tension control variants via adjustable torque curve, torque feedback with sensor and hollow shaft drive.

The taping heads are synchronized with an electronic gearbox to the haul-off device – this ensures high accuracy of the taping pitch. The wedge clamping system ensures secure clamping and centering of the tape reels even at high speeds. The laser sensor continuously records the tape reel diameter.

Optionally, there is the possibility of inching operation with the safety gate open.

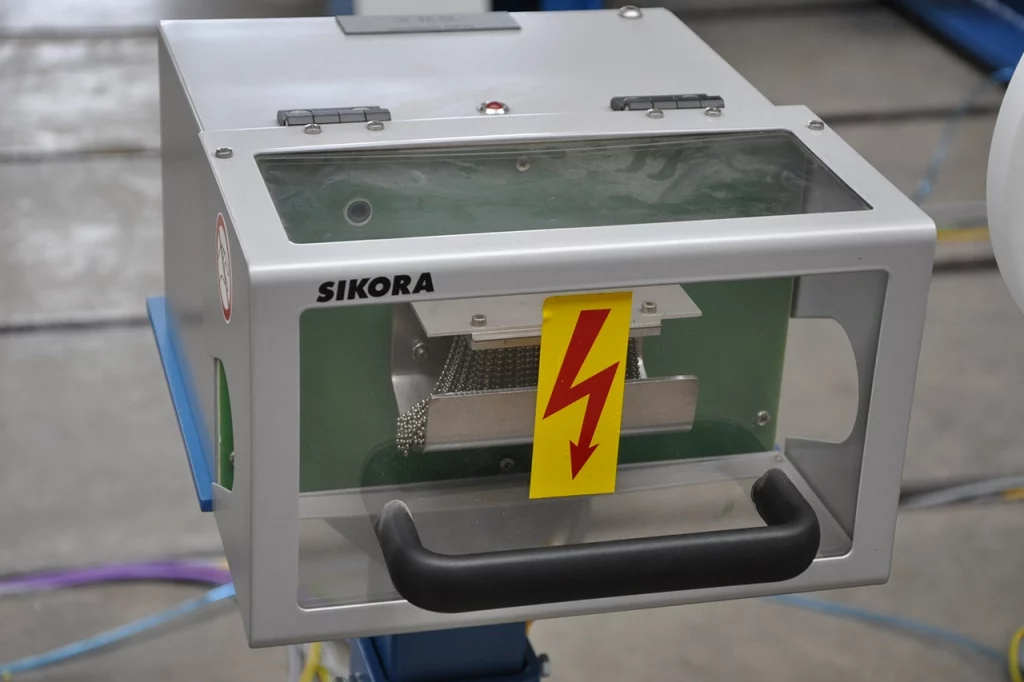

Another highlight: image processing system for regulating taping and quality control.

The horizontal taping machines are very versatile:

- They are suitable for applying tapes and yarns of all kinds (mica, polyamides, polyimides, PTFE, paper, polyester, laminated tapes, aluminum foil, metal, fiberglass, etc), both on single wires or strands as well as single or multi-core cables

- The taping heads can work with both cross wraps and pads

Tangential taping unit

Our tangential taping unit is the perfect solution for applications that require multiple layers of the same tape – and is suitable for two or four tapes. LUKAS tangential taping units impress with their high tape tension constancy and the simple synchronization to existing systems, such as stranding lines, by means of an electronic gearbox with incremental encoder. The end of the tape is detected by an optical sensor. A synchronized stroboscope is available as an option to control the tape guide during production.